newbanner-01

newbanner-02

newbanner-03

newbanner-04

newbanner-05

newbanner-06

newbanner-07

newbanner-08

newbanner-09

newbanner-10

newbanner-11

new-header

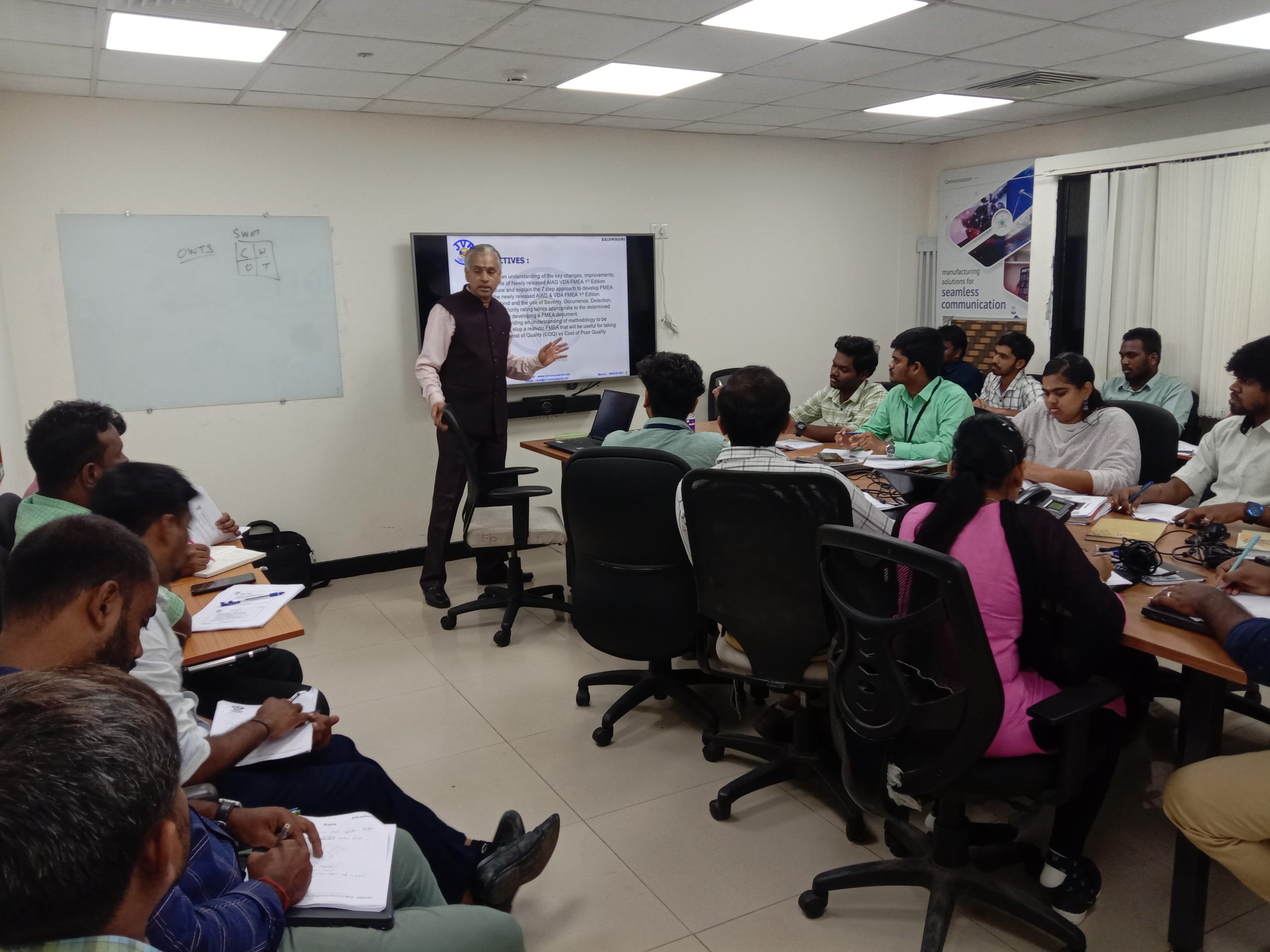

WhatsApp Image 2023-06-23 at 11.44.59 AM

WhatsApp Image 2022-12-23 at 7.34.43 PM (1)

WhatsApp Image 2023-06-06 at 11.16.46 AM

Intl seminar – TQM R1

WhatsApp Image 2023-06-06 at 11.16.45 AM

IMG_20230623_184142

IMG_20230623_100604

IMG_1315

IMG_1316

IMG_1314

IMG_1312

WhatsApp Image 2023-07-08 at 7.01.04 PM

Site Visits

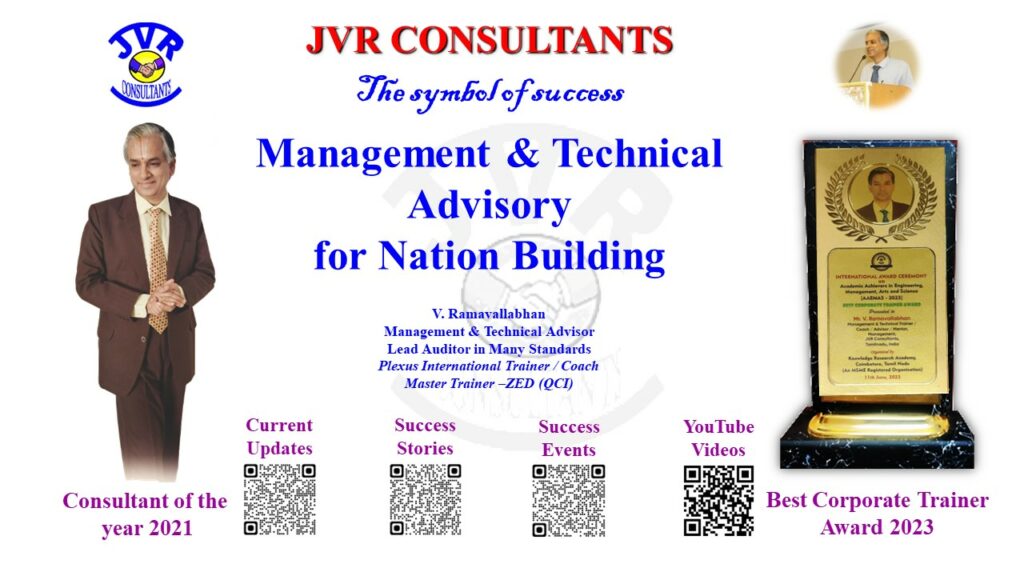

157287